“We have been getting ready to recycle more e-waste by investing in infrastructure, providing grants to local governments, and working with industry.”

Mr Jay Weatherill said these words when the federal and state environment ministers met in Perth in 2009. They were discussing the Extended Producer Responsibility scheme for gathering and recycling electronic waste.

Electronic waste, or e-waste produced worldwide, has snowballed in recent years. This is due to constant technological changes, shorter product lifespans, and shifts in how we store media (like moving from CDs to SSDs to the cloud). Electronics have also become more affordable, making them more accessible for people to buy and replace. As a result, e-waste is now the fastest-growing type of waste globally—amounting to 70% of all toxic waste.

E-waste includes all electronic devices that are no longer usable—broken or outdated. However, not everything labeled as e-waste truly belongs in that category. If still functional or repairable, many old devices can be donated, reused, or refurbished instead of discarded. Still, we all can reduce this waste, and RTS will show you how.

The Most Common Types of e-waste

A broken, outdated, or dead keyboard, computer, microwave, phone, and anything that works by electricity is part of e-waste. As technology advances quickly and people upgrade devices more often, the amount of discarded electronics rises.

Knowing the most common types of e-waste can help individuals and businesses make better decisions about reuse, recycling, or proper disposal. Here are some of the most common types of e-waste:

- Small Electronics — These are items small enough to fit your hands and cover only a small space. Examples are smartphones, tablets, cameras, earbuds, small medical devices, and electric toys.

- Large Appliances — These take up more space and use more electricity. They are refrigerators, washing machines, air conditioners, and other home appliances.

- ventilation equipment

- Computers and Accessories — Laptops, desktops, keyboards, mice, and printers.

- Televisions and Monitors — Older CRT TVs, computer monitors, and modern flat screens.

- Kitchen Appliances — Toasters, microwaves, blenders, and similar devices are common in e-waste landfills.

- Lighting Devices — Items like LED bulbs, lamps, and fluorescent lights also contribute to e-waste.

- Batteries — From single-use batteries to rechargeable ones, they are a growing part of electronic waste.

Proper disposal or recycling of these items is crucial to reduce their environmental impact.

Source: Roadrunner

Why is Electronic Waste Recycling Important?

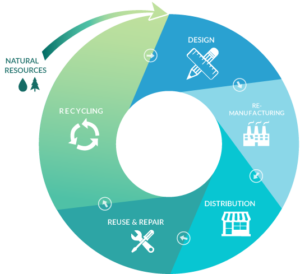

Before examining how electronic waste is recycled, it’s essential to know why. Sustainable waste management helps offset the negative impacts of waste while providing many benefits, mainly by keeping materials in circulation.

Municipalities across the US and the world are raising awareness of the situation and urging corporations across all industries to take greater accountability for their e-waste products. This has a knock-on effect: through producer responsibility, consumers have more choices when repurposing, recycling, or reusing e-waste products.

Today, e-waste management is not keeping pace with our consumption, so the importance of recycling e-waste on a large scale cannot be underestimated. Unless we improve our management systems, we will soon be surrounded by broken electronics.

The Problems With not Recycling e-waste

When e-waste is not managed properly and ends up in landfills or incinerators, it can release harmful chemicals into the air, water, and soil. Some of the dangerous substances that can come from e-waste include:

-

- Lead

- Barium

- Phosphor

- Beryllium

- Cadmium

- Mercury

- Brominated dioxins

- Polycyclic aromatic hydrocarbons

Failing to recycle e-waste also increases the need to mine fresh resources to make new electronics. Many of these devices contain precious metals like gold, silver, platinum, and palladium, already in limited supply. Mining these materials harms the environment through deforestation, soil erosion, and pollution from transportation and processing. By recycling electronics, we can reuse these valuable materials and reduce the need for mining, helping to protect the planet.

Regulations and Standards

Regulations and standards are vital in responsibly managing e-waste. The social activist Pete Seeger said it best: “If it can’t be reduced, reused, repaired, rebuilt, refurbished, refinished, resold, recycled, or composted, then it should be restricted, designed, or removed from production.” Here’s where regulations and standards come in.

These rules ensure that e-waste is handled, recycled, and disposed of in ways that protect the environment and human health. Without clear guidelines, harmful materials like lead, mercury, and cadmium find their way into our air, soil, and water.

In many countries, some laws require businesses and individuals to dispose of e-waste through certified recycling programs. For example, the European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive mandates that manufacturers take responsibility for their products’ safe disposal and recycling. This encourages companies to create devices that are easier to recycle.

In the United States, e-waste regulations vary by state. Some states, like California and New York, have strict e-waste laws, requiring collection programs and banning certain items from landfills. These laws often specify which materials must be recycled and provide guidelines for certified e-waste recyclers.

Globally, the Basel Convention is a critical international agreement that controls the export of hazardous waste, including e-waste, to developing countries. It aims to prevent unsafe and unethical recycling practices in countries with fewer regulations.

Recyclers and handlers must follow strict standards to process e-waste safely. Certification programs like e-Stewards and R2 (Responsible Recycling) ensure recyclers meet high environmental and worker safety standards. These certifications also reassure consumers and businesses that their e-waste is responsibly managed.

Clear and enforced regulations help build a circular economy in which materials from e-waste are reused instead of discarded. Governments, manufacturers, and consumers all have a role in ensuring that e-waste is managed sustainably and safely.

What are the Challenges of Recycling e-waste?

In 2019, the United Nations warned that if we don’t change our habits, the world could produce 120 million tons of e-waste every year by 2050.

The first issue is e-waste management. This is because most electronics contain harmful substances that call for careful handling. Without proper training, gear, and storage, you risk contamination—to the handler and to the environment.

Another predicament is when e-waste lands in developing countries’ landfills. In these scenarios, garbage collectors often break down electronics in unsafe conditions in these places without proper regulations.

Informal recycling methods, like burning plastics to extract metals, also pose a problem because they release harmful emissions into the air, causing health and environmental problems. The good news is that these risks can be reduced by choosing reputable recyclers who follow safe practices.

Why E-Waste Recycling is So Complicated

Recycling e-waste isn’t as simple as it seems. Electronics come in many shapes and sizes, from fridges to smartphones, and each type needs different recycling methods. Even a single electronic item is often made from plastic, metal, and glass. Separating these materials can be time-consuming, expensive, and tricky compared to recycling more straightforward items like cans or glass bottles.

Programs for collecting e-waste also vary. Some municipal or private collections may not accept certain items, like microwaves or refrigerators. However, community events focused on e-waste recycling may accept large appliances because they are mostly made of metal or sturdy plastics.

Finding Solutions for E-Waste

Despite these challenges, systems are in place to address the e-waste problem. RTS has an app that helps organizations schedule bulk collections and offer diversion solutions. Such recycling initiatives follow specific steps to process e-waste and recover valuable materials safely.

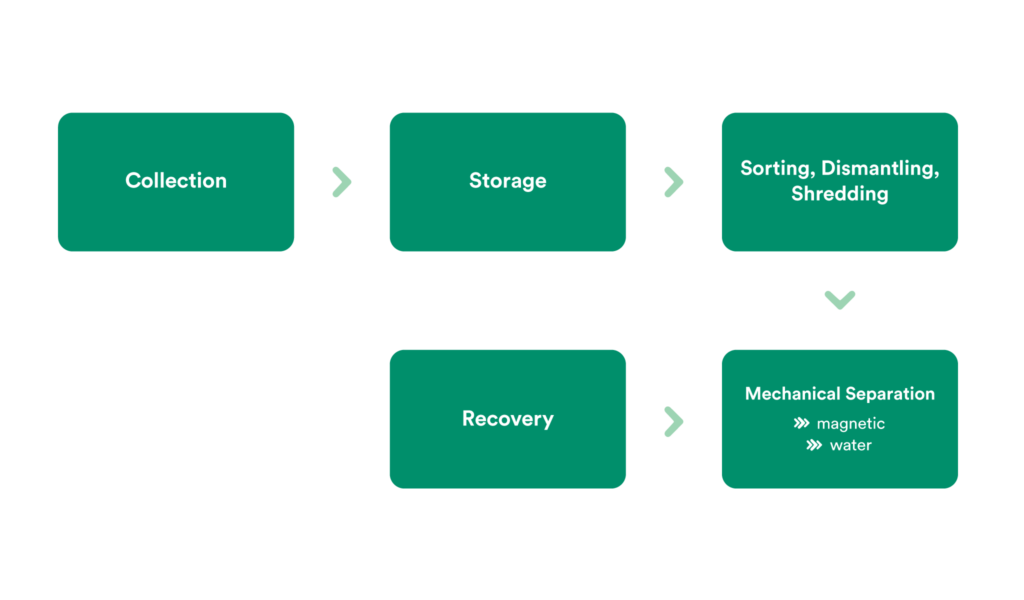

E-waste Recycling Process Flowchart

Collection Storage Sorting, Dismantling, Shredding Mechanical Separation Magnetic Water Recovery

The e-waste recycling process

Recycling e-waste involves several steps, each designed to handle and recover valuable materials from old electronic devices safely. Let’s look at this process, which is explained in simple terms.

Step 1: Collection

The first step is gathering old electronics through designated recycling bins, drop-off centers, or take-back programs. Local governments, businesses, or community events may run these collection points. Some services even offer on-demand pickups to make recycling easier.

In this step proper separation rules. Many centers use bins for various types of e-waste, such as batteries, phones, or computers, to prevent harmful substances from mixing. Batteries, for instance, require special care because they can cause fires or leak toxic chemicals. We have been able to recycle about 350 lbs of batteries so far.

Step 2: Safe Storage

Once collected, e-waste is stored safely until it’s ready for processing. This is especially important for items like old TVs and monitor screens containing lead, which can harm people and the environment if mishandled. In the past, glass from these screens was recycled into new products, but declining demand has left much of it in storage.

Step 3: Sorting, Dismantling, and Shredding

Next, the e-waste goes through manual sorting. Workers remove specific items that need special processing, such as batteries or lightbulbs. Some parts, like reusable components or valuable metals, are separated at this stage.

After sorting, the remaining e-waste is shredded into tiny pieces, usually just a few centimeters in size. This makes separating materials like metals, plastics, and glass more accessible.

Step 4: Mechanical Separation

This step uses advanced machines to sort materials based on their properties:

Magnetic Separation

Large magnets pull out metals like steel and iron. Nonferrous metals like aluminum and copper are separated using eddy currents.

Water Separation

Plastic and glass pieces are separated using water. Heavy materials sink, while lighter ones float, making it easier to sort and purify each type.

These processes ensure that every material is collected and prepared for the next stage.

Step 5: Material Recovery

Finally, the separated materials are cleaned and prepared for reuse. Metals like steel and copper may be used in smelting plants to create new products. Plastics might be melted down and turned into new items, while reusable components can go directly back into production.

This stage is vital for creating a circular economy. By recovering and reusing materials, we reduce the need for mining raw resources, which helps protect the environment and save energy.

Why It Matters

Recycling e-waste is about more than reducing clutter. It prevents toxic substances from polluting the air, water, and soil while giving new life to valuable materials. By understanding and supporting this process, we can all help create a cleaner, greener future.

Materials Extracted from E-Waste

When electronic devices like phones, computers, and TVs reach the end of their life, they can be recycled to recover valuable materials. These materials are often crucial for creating new products, and recycling helps reduce the need for mining, which can harm the environment.

Metals

One of the most common and valuable materials extracted from e-waste is metal—gold, silver, platinum, and copper. These metals are used in circuit boards, connectors, and other devices. Recycling these metals not only helps reduce the need for mining but also prevents pollution caused by extracting metals from the earth.

Rare Earth Elements

Another important group of materials found in e-waste is rare earth elements—neodymium and dysprosium. These are used to produce high-tech devices, including smartphones, electric cars, and wind turbines. Although they are rare in nature, these elements are valuable and can be recycled from old electronics.

Plastic

Many electronics contain plastic parts, which can be recycled to produce new devices or other products. While plastic recycling can be tricky due to the variety of types used in electronics, it’s still an essential step in keeping waste out of landfills.

Glass

Glass from old TVs and monitors, especially the glass in cathode ray tubes (CRTs), is also a key material that can be recycled. It’s often mixed with lead, which can be harmful, so it must be handled carefully. This glass can be cleaned and reused in other products.

How The Universal Recycling Process Differs Across Common Items

While this represents the general e-waste management recycling process, many items have their own unique processes. For example:

The Recycling Process for Batteries

When batteries arrive at a recycling site, they are sorted by type—lead-acid, nickel-cadmium, nickel-metal-hydride, or lithium-ion. Any plastic parts, like casings and insulation, are burned away, and a scrubber is used to capture harmful gases and particles created during the burning process.

Next, the remaining metal parts are chopped into smaller pieces and heated until the metal melts. As the metal liquefies, non-metal materials like plastics burn off and rise to the surface, forming a slag layer, which is then removed.

Some recycling centers send the unprocessed metal to specialized plants for further recycling, while others collect the metals as they separate based on their weight. For example, cadmium, a toxic metal, evaporates during the process and is collected through condensation to prevent it from polluting the environment.

The Recycling Process for Cathode Ray Tubes

Cathode Ray Tubes (CRTs), commonly found in older televisions and computer monitors, are one of the hardest types of electronic waste to recycle. The main issue with CRTs is that they often contain large amounts of lead—sometimes as much as four pounds in one monitor or TV. This lead is hazardous to the environment and can’t be safely recycled with regular glass.

While CRTs are becoming less common as newer technology takes over, a lot of old CRT equipment still needs to be recycled. This means that recycling centers must handle CRTs very carefully. The glass from these devices, which is heavily contaminated with lead, requires special treatment to ensure it doesn’t cause harm. Unfortunately, this makes recycling CRTs a complex and costly process.

The E-waste Recycling Process for Computers and Laptops

Recycling laptops and computers follows a similar process to other types of e-waste but with a stronger focus on sorting and separating parts. Many computer components from broken machines can be reused in new computers, reducing the need for extra resources.

An essential part of recycling electronics is data destruction. This ensures that any personal or sensitive information is securely erased. Data is wiped digitally on reusable hard drives, while physical methods like shredding are used for others. This is similar to how businesses shred confidential paper documents to protect information. In today’s digital age, destroying data on hard drives is just as important.

The Recycling Process for Mobile Phones and Tablets

Recycling mobile phones and tablets involves collectors dismantling devices to separate components like screens, batteries, circuit boards, and casings.

Lithium-ion batteries are removed and recycled to prevent fire hazards. Screens are processed to recover valuable metals while safely disposing of hazardous materials like mercury. Circuit boards are shredded to extract precious metals, including gold and silver, while casings are melted for reuse.

At the End of the Day

Finally, the Basel Convention identified e-waste as a problem in 2002. However, we are still far from reaching a world with zero e-waste. Our increasing reliance on digital devices means that without better recycling programs, we risk draining natural resources and creating massive e-scrap.

However, there is hope that we can strive for a more circular economy with e-waste. Both businesses and individuals can make a difference through conscientious consumption, reduction, and reuse. Eventually, this will push manufacturers towards more easily recyclable devices through producer responsibility programs.

For more information on making the most of your e-waste recycling, or to find out how to optimize your current waste management operations, contact one of our TRUE advisors today. For more information on sustainable materials, waste reduction, and recycling, subscribe to the RTS blog.

Additionally, if you’d like to learn more about recycling e-waste in locations within the US, please refer to our other electronics recycling guides:

Sources

QuoteFancy. (n.d.). Retrieved December 5, 2024, from https://quotefancy.com/quote/1461198/Jay-Weatherill-We-have-been-getting-ready-to-recycle-more-e-waste-by-investing-in

Sydney Morning Herald. (2009, November 5). SA ready for e-waste recycling: Minister. Retrieved December 5, 2024, from https://www.smh.com.au/national/sa-ready-for-ewaste-recycling-minister-20091105-hywm.html

The World Counts. (n.d.). Electronic waste facts. Retrieved December 5, 2024, from https://www.theworldcounts.com/stories/electronic-waste-facts

RTS. (n.d.). What is sustainable waste management? Retrieved December 5, 2024, from https://www.rts.com/blog/what-is-sustainable-waste-management/

RTS. (n.d.). What is extended producer responsibility? Retrieved December 5, 2024, from https://www.rts.com/blog/what-is-extended-producer-responsibility/

EcoWatch. (2020, December 14). How to solve the e-waste crisis. Retrieved December 5, 2024, from https://www.ecowatch.com/ewaste-consumer-electronics-2649872499.html

Polish Journal of Environmental Studies. (n.d.). Environmental effects of electrical and electronic waste on water and soil: A review. Retrieved December 5, 2024, from https://www.pjoes.com/Environmental-Effects-of-Electrical-and-Electronic-nWaste-on-Water-and-Soil-A-Review,144194,0,2.html

European Union. (n.d.). Waste electrical and electronic equipment (WEEE) responsibilities. Retrieved December 5, 2024, from https://europa.eu/youreurope/business/product-requirements/recycling-waste-management/weee-responsibilities/index_en.htm

CalRecycle. (n.d.). Electronics statutes. Retrieved December 5, 2024, from https://calrecycle.ca.gov/electronics/statutes/

NYC Department of Sanitation. (n.d.). Electronics disposal. Retrieved December 5, 2024, from https://www.nyc.gov/site/dsny/collection/get-rid-of/electronics.page

Basel Convention. (n.d.). The Basel Convention overview. Retrieved December 5, 2024, from https://www.basel.int/theconvention/overview/tabid/1271/default.aspx

e-Stewards. (n.d.). Retrieved December 5, 2024, from https://e-stewards.org/

Sustainable Electronics Recycling International. (n.d.). R2 certification. Retrieved December 5, 2024, from https://sustainableelectronics.org/r2/

World Economic Forum. (2019). A new circular vision for electronics. Retrieved December 5, 2024, from https://www3.weforum.org/docs/WEF_A_New_Circular_Vision_for_Electronics.pdf

RTS. (n.d.). Spotlight: 4thBin and e-waste. Retrieved December 5, 2024, from https://www.rts.com/blog/spotlight-4thbin-and-e-waste/

RTS. (n.d.). Waste management app. Retrieved December 5, 2024, from https://www.rts.com/services/waste-management-app/

RTS. (n.d.). The complete plastics recycling process. Retrieved December 5, 2024, from https://www.rts.com/blog/the-complete-plastics-recycling-process-rts/

Stanford Advanced Materials. (n.d.). Rare earth elements: Neodymium vs. Dysprosium. Retrieved December 5, 2024, from https://www.stanfordmaterials.com/blog/rare-earth-elements-neodymium-vs-dysprosium.html

ScienceDirect. (2021). Abstract of S0921344921005450. Retrieved December 5, 2024, from https://www.sciencedirect.com/science/article/abs/pii/S0921344921005450

U.S. Environmental Protection Agency. (n.d.). Electronic waste and demolition. Retrieved December 5, 2024, from https://www.epa.gov/large-scale-residential-demolition/electronic-waste-and-demolition

Basel Convention. (n.d.). Overview: E-waste. Retrieved December 5, 2024, from https://www.basel.int/Implementation/Ewaste/Overview/tabid/4063/Default.aspx

RTS. (n.d.). How to recycle scrap metal. Retrieved December 5, 2024, from https://www.rts.com/blog/how-to-recycle-scrap-metal/